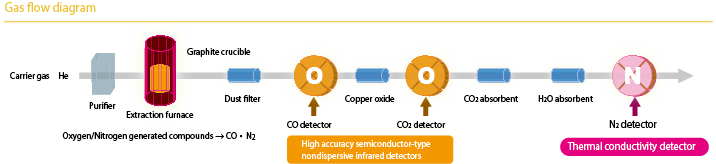

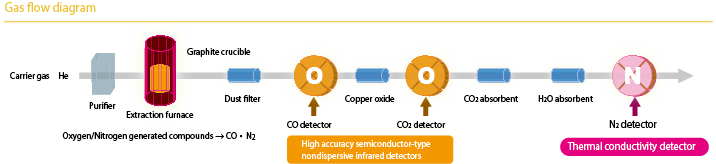

Principle and Gas flow diagram

The sample is placed in a graphite crucible and the crucible is maintained between the upper and the lower electrode of the impulse furnace. A high current power passes through the crucible to create a high temperature.

The oxide in the sample reacts with the graphite crucible, and is extracted as carbon monoxide (CO), and carried together with the carrier gas. The extracted gas is directly analysed after the dust filter. According to the oxygen concentration, it is determined by CO or CO2 after pass throw oxidizer (Copper Oxide) with a non dispersive Infra-Red analyser (NDIR).

The Hydrogen is determined with a non dispersive Infra Red analyser as H2O after H2 passes through the oxidizer (Copper Oxide).

The Nitrogen in the sample is extracted as nitrogen gas (N2) and its concentration is determined by a thermal conductivity detector (TCD).

Super High Performance

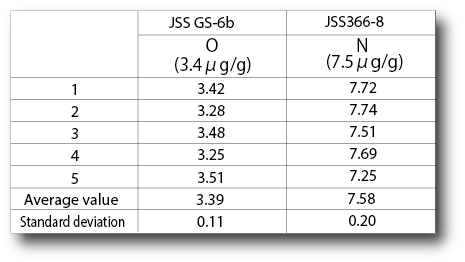

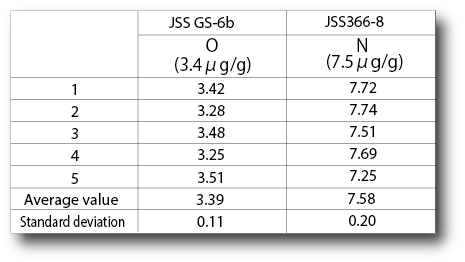

Wide range and high accuracy measurement

*Range: Oxygen:

0-5%, Nitrogen: 0-3%, Hydrogen: 0-0.25%

*Accuracy:

σn-1≦0.3ppm or CV≦1.0% for STD sample

σn-1≦0.02ppm or CV≦0.5% for Reference gas

*Accuracy H:

σn-1≦0.04ppm or RSD≦2.0% for Reference gas

Double detectors of oxygen (CO and CO2), long type cell and optimized design of TCD provide wide range measurements.

Optimization of the signal processing reduces by half the electrical noise compared to conventional model.

Standard

EMGA fulfils requirements of the standard method for analysis of steel titanium, ceramics etc…

EX)

*ISO10720, ISO17053

*JIS G1228

*ASTM E1019, ASTM E1569, ASTM E1409

User-friendly Software

Measurement Window

Simple software allows easy handling.

Extracted gas signals are displayed in real time numerically and also as curves together with temperature level. Graphs are saved automatically.

In the measurement window, sample weight can be registered automatically. Results are saved in a data table for easy management.

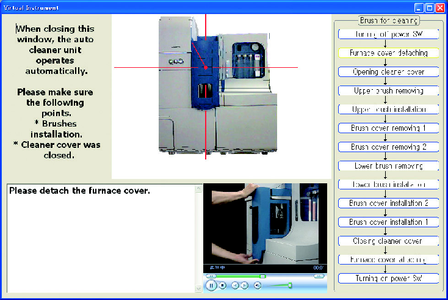

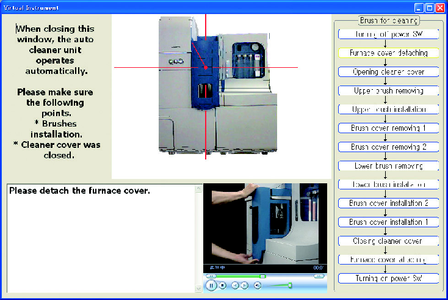

HORIBA originality-Maintenance navigator

Maintenance counter informs users at the timing of consumables replacement to keep high accuracy means.

And as navigator describes the easy to understand procedure for the replacing parts, operator can do maintenance works with absolutely no experience and technical knowledge.

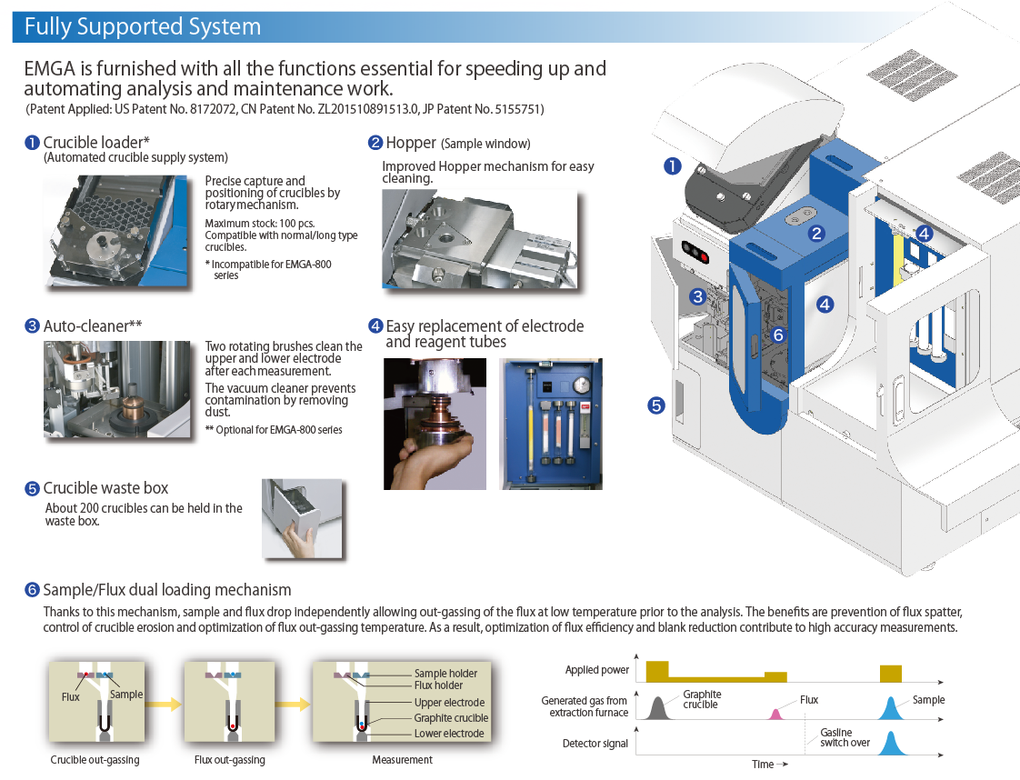

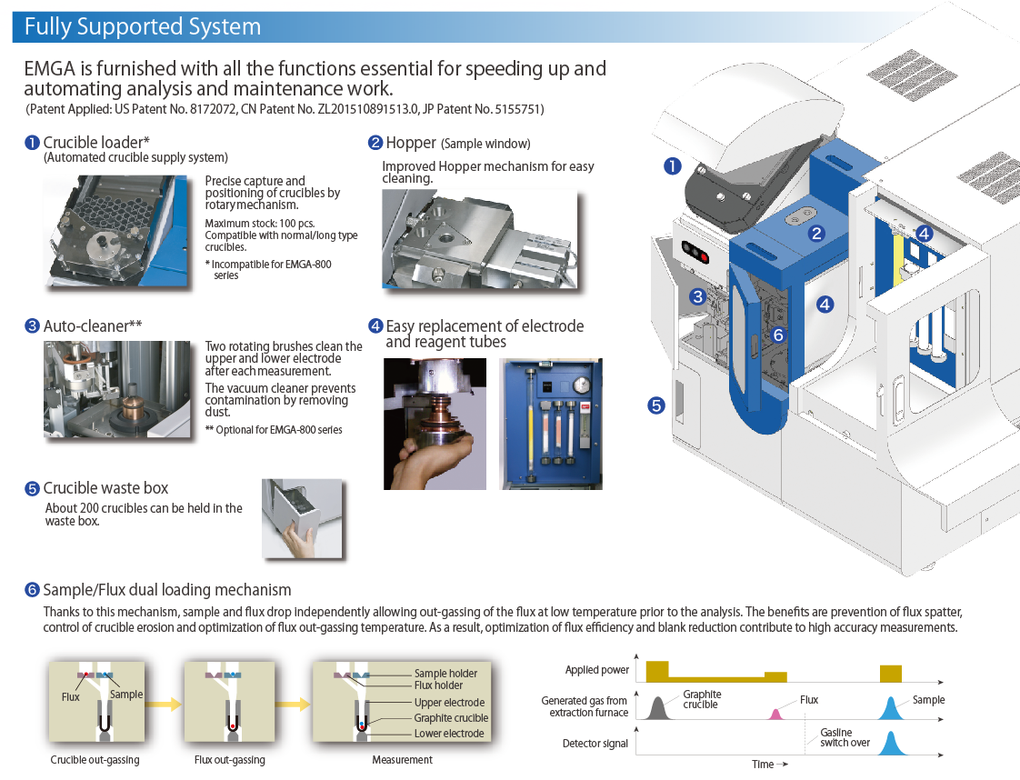

Fully Supported Accessories give simple operation