The number of detectors, angular range, and layout each contribute to overall system performance.

The LA-960V2 is designed and built to provide the same experience regardless of manufacture date, operator skill, or geographic location. Achieve unmatched instrument agreement without the hassle of correlation.

Always make perfect measurements with computer-controlled laser alignment. The alignment process is finished in only a few seconds with HORIBA’s innovative approach.

The LA-960V2 is a highly refined particle size analyzer capable of accurately measuring NIST-traceable size standards within 0.6% of specification. Fully compliant with ISO 13320 recommendations regarding the measurement of materials on the D10, D50, and D90.

Sample-to-sample analysis in less than 60 seconds

The HORIBA LA-960V2 wet circulation system is an easy, fast and very powerful dispersion system. The standard wet system offers a full package of a dispersant fill pump, liquid level sensor, circulation pump, 30 W in-line ultrasonic probe, and drain valve, which is all software-controlled for true one-button operation. This advanced design provides highly reproducible particle size results.

Automated, powerful dry-powder dispersion

The LA-960V2 PowderJet combines several unique and patented features to provide the most reproducible dry measurements. Use the Auto Measurement function to control vacuum, air pressure, powder flow, start/stop conditions, measurement duration, and data processing. Designed to handle every application including small sample amounts, friable powders, and highly agglomerated materials.

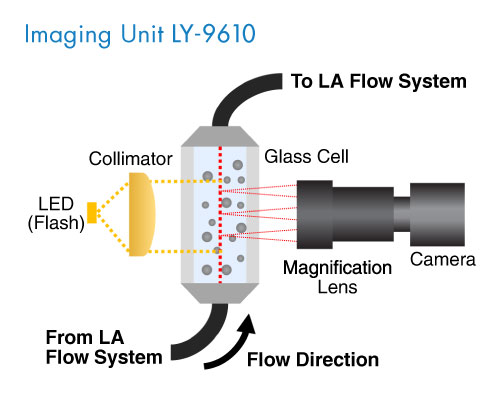

The imaging unit allows real-time observation, particle image acquisition, and assessment of the particles in the wet circulation system. It is small and integrated in the main unit without increasing instrument footprint!

Features

Functions

The only photosynthesis system capable of measuring combined gas exchange and fluorescence from leaves and aquatic samples.

Improve your operations with these accessories specifically designed for the Stuart Aquatron Water Stills.

The Quorum Coolstage is a Peltier-cooled cooling stage for scanning electron microscopy (SEM), low vacuum (LV) or variable pressure (VP) applications.

You may contact our specialists by accomplishing form below.

You may contact our specialists by accomplishing form below.