ASTM D1655, 7566, and D3241

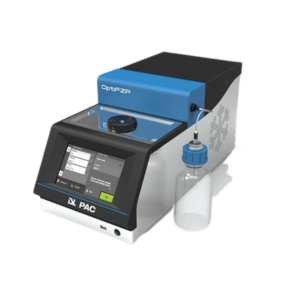

Ellipsometric jet fuel thermal oxidation heater tube scanner. Our new OptiReader provides pass/fail results with a full 2D and 3D thickness map defining maximum deposit thickness and volume. Results are not only fast, but also highly precise and accurate. The user interface is so simple it doesn’t require any training which saves time and money.

OptiReader is now listed in jet fuel standards ASTM D1655 and D7566. With this new development, the OptiReader which measures the fuel deposit depths on heater tubes used in the ASTM D3241 JFTOT test, can now serve as a key test for certifying Jet Fuel and Synthetic Aviation Fuel (SAF) for use in commercial and military aviation.

- No training or analytical knowledge required

- User friendly interface on a large 10.8 color touchscreen

- Objective pass/fail results

- Quantifiable HT deposit thinkness and volume

- Unified test report with results from JFTOT & OptiReader

- Data integration using PAC Intelligent Heater Tubes – at no extra cost

- Over the top precision – better than ASTM D3241 requirement

- Validation system with standard tubes generated by Atomic Layer Deposition

- Full mapping is completed in less than 10 minutes