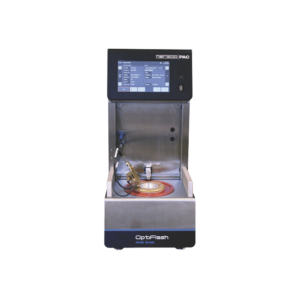

Viscosity Measurement with ViscoLab PVT | Safe and cost-effective to own and operate, the ViscoLab PVT is mercury-free and requires only 6 ml of sample. It also provides statistical certainty that ensures sample conditions are stable, accurate, and repeatable. It measures gas and gas condensates in addition to fluid samples. The ViscoLab PVTs extraordinary capabilities make it an ideal choice for the most critical and challenging applications.

This high pressure viscometer combines a ViscoPro processor with either a Cambridge Viscosity 440 or 443 sensor. The 440 sensor provides continuous operation up to 20,000 psi while the 443 sensor is designed to operate up to 30,000 psi. The system employs an integrated re-circulating bath for tight temperature control.

- Easy to Use and Maintain

- Requires small sample size – 6ml of sample per measurement

- Incorporates digital pressure gauge

- Includes intuitive and easy to use VISCO PVT software to store and archive test data

- Reduces operator intervention since sample handling occurs direct from the pressure canister or via pressure generator

- Mercury free

- Enhanced Features

- Measures gas and gas condensates in addition to fluid sample

- High accuracy and reliability within extreme operation conditions (up to 20,000 psi and up to 190°C)

- Small footprint

- Analysis time in under 4 hours