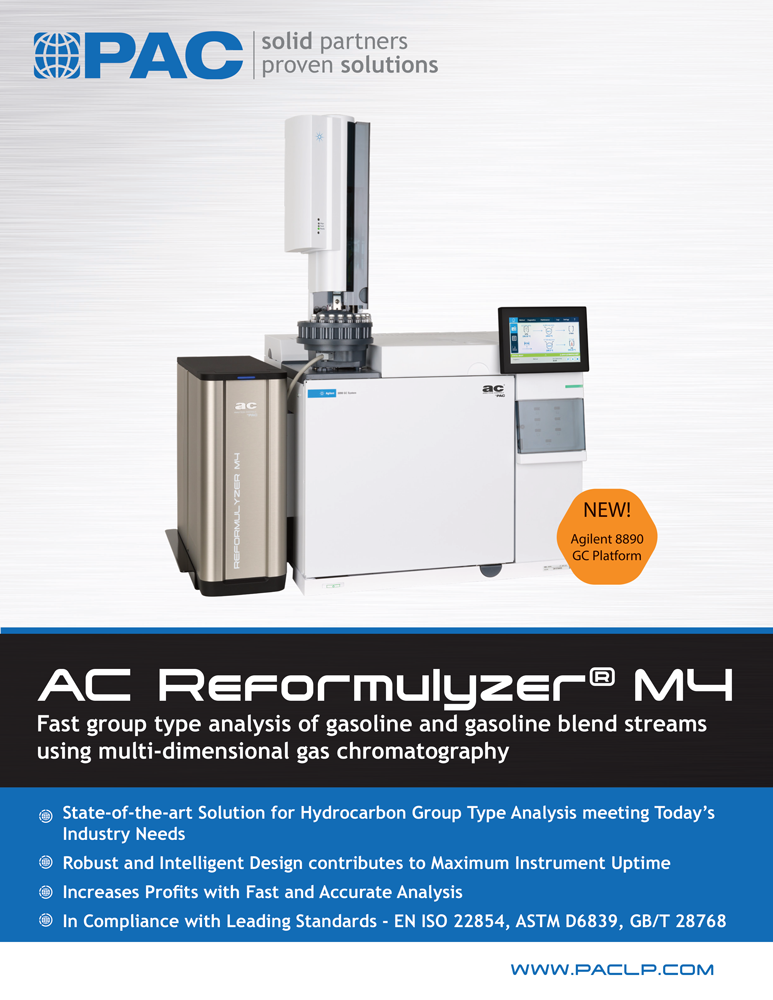

Top Reasons to Choose

AC Reformulyzer® M4

Excellent Performance for High Return on Investment

Easy-to-use, Dedicated Reformulyzer Software Enables 24/7 Operation

Separation by Component Groups Enable Highly Accurate Results Regardless of Sample Matrix

Recognized Industry-standard Technology Enables Compliancy to Many Fuel Specifications

——

By using a proprietary, multi-dimensional separation approach which is unrivalled in the industry, coupled with simple and robust detection technology, highly accurate results are obtained regardless of sample matrix. Easy-to-use, dedicated Reformulyzer software helps analysts and operators start analysis with just a few clicks and generate reliable data 24/7.

Increase Revenue with increased daily sample capacity

The Reformulyzer M4’s short analysis time allows to run up to 100% more samples per day* and it enables labs to comply to the significant in-tank and in-ship blending time constraints related to key-point analysis.

Reduce Operational Cost with Robust Design and Advanced Technology

The Reformulyzer M4’s advanced technology significantly reduces maintenance and system down-time. In combination with the improved sample capacity the total operational cost per sample is reduced by 50%.*

*View ROI Case Study Results in Reformulyzer Brochure