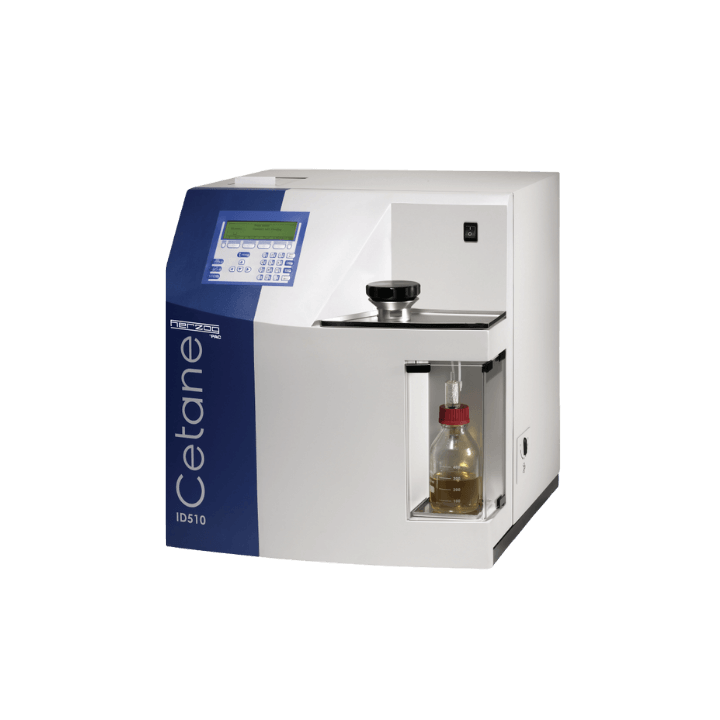

PAC Herzog CID 510 Cetane Ignition Delay

WORLD-CLASS ANALYSIS OF DERIVED CETANE NUMBER

The Cetane Ignition Delay CID 510 is a compact and easy to use analyzer, with fully automatic analysis and calibration sequences, offering analysis with extremely high precision.

Excellent accuracy of derived cetane number for diesel fuels

An accurate analysis of the derived cetane number (DCN) is an important instrument for diesel fuels mixers and biodiesels and refineries, to keep fuel consistency and quality. The new laws on fuels for emission reduction and a higher fuel efficiency require higher cetane numbers. So, the use of cetane improvers in diesel fuel is increasing, leading to a higher demand for cetane number measurement technologies, since the cetane index calculation does not work for samples with improved cetane number and for biodiesel. The existing technologies such as the CFR Engine and CVCC methods do not satisfy the requirements on the market because of their high capital and operational costs, of difficult operation and low system performance.

Cetane analyzer Herzog ID 510 – ASTM D7668, ISO EN 16715

Herzog by PAC developed Cetane ID (CID) 510, a compact and easy-to-use analyzer, with completely automatic analysis and calibration sequences, which offers analyses with extremely high precision. It provides a perfect correlation to ASTM D613 and is ideal for biodiesel and biodiesel mix, as well as for samples with improved cetane number. PAC Cetane ID 510 is approved as ASTM D7668 standard “Standard Test Method for Determination of Derived Cetane Number (DCN) of Diesel Fuel Oils—Ignition Delay and Combustion Delay Using a Constant Volume Combustion Chamber Method”. CID 510 offers significant economic benefits: low capital cost (2 fold cheaper than traditional systems), minimum operational cost, and requires a very smaller space on the workbench and no separate rooms. The fast workflow contributes to a high lab throughput and long term stability and the automatic calibration of CID reduce the risks of down times.

Advanced and unique design

The fuel injection system is a modern common rail high pressure electronic injection system, which offers an extreme precision. The common rail injector allows for very higher injection pressures (up to 1500 bars), producing a completely volatilized and hence better test sample, a sooting-free combustion as compared with other instruments with Constant Volume Combustion Chamber (CVCC). The faster evaporation makes the pre-flame reactions viewable. The pre-flame clearly shows the effects of cetane improvers such as 2-ethylhexylnitrate (EHN) on the combustion process. Finally, the electronic control injector guarantees high precision in the fuel injection volume, making the results more repeatable.

Features and benefits

The Cetane Ignition Delay CID 510 is a compact and easy to use analyzer, with fully automatic analysis and calibration sequences, offering analysis with extremely high precision.

– Fast and precise analysis of derived cetane number for diesel fuels.

– Easy to use, the one button operation allows for a completely automatic test and a high lab throughput

– The highly accurate performance surpasses the CFR Engine and other CVCC methods results

– No carry-over effect from previous samples

– The long term stability and the automatic calibration minimize risks for down times

– Various advanced features contribute to high safety standards

System Description

The CDI 510 system with “one button operation” for a simple and comfortable use, includes the following features:

– Bench unit requiring a minimal workbench space

– Electronic controlled advanced fuel injection model for a high accuracy of fuel injection volume

– Unique combustion chamber with multi-nozzle high pressure standard injector, for a sooting free combustion.

– Built-in fuel filter with automatic replacement message

– Automatic diagnostics features, for example automatic leaks check for the combustion chamber

– Built-in printer with flexible reports formats

– Data export to LIMS and Excel

– Standalone instrument – a PC is not required

Excellent precision and perfect correlation with ASTM D613

Only the Herzog CID 510 system by PAC includes the ignition delay (ID) and combustion delay (CD) measurements to forecast the correct derived cetane number as compared with ASTM D613 for fuel 2 and fuel 3.

High safety standards

CID 510 includes various features for a safe operation:

– Built-in fire monitoring and suppression system

– Overpressure protection for the combustion chamber and the injection system

– Overpressure switch and cooler flow rate sensor to protect the injector and pressure sensor

– The fuel level sensor avoids the dry operation of the injection system