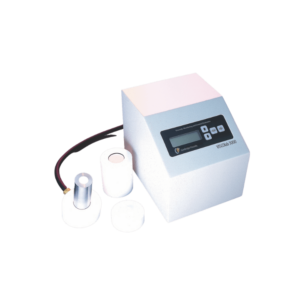

PAC Herzog OptiFlash Cleveland Open Cup features

- Built-in fire extinguisher with ultra fast optical detector

- Robust hardware design

- Optional bitumen rake to remove possible surface skin

- Automatic lift-arm

- User-friendly interface

- Easy cleaning and low maintenance

Standards: ASTM D92; ISO 2592; EN ISO 2592; IP 36; GB/T 3536

Temperature Measurement: Intelligent Pt 100 probe with built in Calibration, 10 Calibration Points,

Glass or Metal Pt 100, Temperature range -50°C to +450°C,

Resolution 0.1°C

Heating System: Heater plate for uniform heating of the cup, 2 Heat Rates,

Test Method or user-defined Heat Rate from 0.5 to 17 °C/min.

Rake for skin forming samples: Automatic Skin Rake, for accurate handling of skin forming samplesIgnition SourceIntelligent Electric Igniter with automatic power management over life time or automatic Gas Ignition with gas flame monitoring,Test Method or user-defined Test Interval from 0.5 to 50 °C

Barometric Pressure: SensorBuilt in barometric pressure sensor for automatic barometric pressure correction for the Flash Point, Pressure units mbar, hPa, kPa, mmHg or Torr.

Flash Detection System: Ionization Flash Point Detection or unique Optical Flash Point Detection which can detect Flash Point of all sample types

User Interface: 7” Colored Touch screen, Alpha Numeric data input, Barcode Reader; Languages: English, German, Spanish, Portuguese, French, Chinese, Polish, Italian, Russian

Result Documentation: 500 results, 200 products, User defined result reports for printer and LIMsPrinterExternal printer through USB Interface and with PCL5 or higher; Netware printer through Ethernet with PCL5 or higher and Internet Print Protocol IPP; Automatic print out

LIMS interface: Ethernet or RS232, User defined Data String, Automatic LIMS transfer

Data Export: USB Memory Stick, Import into Excel

QC-Functions: Automatic QC-sample handling and QC-Chart

SAFETY FEATURES:

Fire Extinguisher:2 built-in optical fire sensors for detection of fire around the test cup,

Fire extinguishing System with external Inert gas,Alarm relay to link OptiFlash to a lab alarm system

Safety pre-test: By doing safety pretests the unit can detect high volatile contamination in normally high flash point samples and avoid a risk of fire

Alarm Functions: Automatic detection of method or safety violations. User selects test termination or alarm message

Password Protection: Different Access levels for Operator, Service or Lab Manager

Calibration & Diagnostics: User defined Calibration Intervals Automatic Diagnostic functions

Accessories:

Barcode Reader

Ticket printer, A4 USB printer, Netware Printer

Metal Sample Temperature Sensor

OPERATING REQUIREMENTS:

Electrical: 115V or 230VAC 10% switchable; 50-60Hz; 1100 W. Protection class II, Pollution degree 2

Ambient Conditions: Temperature: max. 10° to 35°C; recommended 15° to 25°C. Humidity: 80% rel. at 35°C

Storage temperature: -15 to +55°C

Dimensions: 25 cm (9.85”) wide, 51 cm (22”) deep, 56 cm (20.1”) tall

Weight: 25kg, (55 lb)

For more information, contact us.