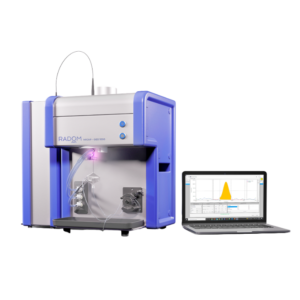

Features

World-class baseline repeatability

Both NEXTA DSC600 and DSC200 use an advanced heat-flow design in the sensor. This allows the heat from the heat sink transferred evenly to the sample and the reference, resulting in the high baseline stability. Together with a furnace built with a low-heat-capacity three-layered insulation design, this allows the NEXTA DSC achieves world-class baseline repeatability and stability.

World-class sensitivity

The NEXTA DSC600 has a proprietary thermopile-type DSC sensor. By using differential scanning calorimetry (DSC signal) temperature sensor thermocouples connected in series and multiplexed, the NEXTA DSCs achieve a high sensitivity of 0.1 µW or lower, enabling measurement of even smaller samples.

Wider temperature range for Real View® DSC

The Real View Sample Observation Unit has a built-in two-megapixel high-resolution camera that supports visual observation of the sample. The viewport (observation window) has a heating mechanism that extends the measurement range from the conventionally observable range of room temperature and above down to the low temperature of -50°C. This enables the user to observe processes such as the crystallization and the glass transition, for example, of samples at low temperatures. This offers a unique capability for understanding material behavior.

Specific heat capacity determination by temperature modulated DSC method

The reversing heat flow (which shows glass transition and melting) and non-reversing heat flow (which shows enthalpy relaxation, curing, evaporation, decomposition, etc) are obtained from a modulated DSC measurement. This is useful when these transitions or reactions overlap or stress relief obscures a transition. The modulated DSC method can also be used for determining the specific heat capacity (Cp), which simplifies measuring Cp.

Specifications

| DSC600 | DSC200 | |

|---|---|---|

| Measurement principle | Heat Flux | |

| Temperature range | -150℃~725℃ | |

| DSC dynamice range | ±100mW | ±200mW |

| RMS noise / Sensitivity | 0.05μW/0.1μW | 0.1μW/0.2μW |

| Calorimetric precision | ±0.05% * Calculated from the standard deviation (1σ/average value in In 10 consecutive measurement) | |

| Baseline repeatability | ±5μW * Electrical Cooling Unit : -50~300˚C, 10˚C/min | |

| Programmable rate | 0.01℃~100℃/min | |

| Purge gas | Air, Inert gas | |

| Purge gas control | Mass flow controller, 2 lines | |

| Auto Sampler * | Max.50 samples | |

| Electrical Cooling Unit * | -80℃~500℃ | |

| Auto LN2 Gas Cooling Unit * | -150℃~725℃ | |

| Auto Air Cooling Unit * | Ambient ~725℃ | |

*Optional