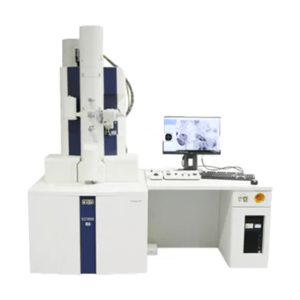

Hitachi NEXTA DMA Dynamic Mechanical Analyzer Philippines

The Dynamic Mechanical Analysis (DMA) technique enhances sensitivity in measuring glass transition, material stiffness and the impact of frequency on mechanical traits. It gauges the viscoelastic properties of materials. Reliable for product engineers in applied research and materials development, DMA analyzers offer precise measurements of mechanical properties for simple and complex materials.

Our DMA features an innovative Real View® camera system that offers real-time observation during measurements, aiding in understanding unexpected behaviors like sample damage or color shifts. It also ensures the verification of data point reliability, even after the measurement process is concluded. And, with its exceptionally wide measurement range and rapid electronic response, our DMA is the perfect tool for assessing both stiff and soft samples, while also capturing rapid modulus changes.

Product Highlights

Comprehensive material characterization made easy

- Utilize the 20N force range for analyzing stiff materials, ideal for carbon fiber composites and other high-performance materials.

- Access a wide applied force range with 5E-6N resolution and minimal output signal noise, enabling the detection and resolution of even the smallest transitions.

- Opt from air, liquid nitrogen (LN2) or electrical gas cooling options; electrical gas cooling relies on power, eliminating external resources, while our LN2 cooling platform reduces its consumption by up to 30%

- Easily validate your results during or after analysis with the Lissajous monitor function, ensuring confidence in your results.

- The Real View® system, various measuring modes, rapid modulus change detection and advanced analysis provide versatile insights for research.

- Maximize convenience with our user-friendly ‘Guidance Mode’ software, providing step-by-step measurement and analysis guidance for non-experts. Advanced options such as master curve (TTS) and activation energy calculations support various applications and are included as standard.

- Our DMA instrument meets ISO, ASTM, DIN, and JIS standards, with essential specifications like ISO 6721-11, ASTM D7028 – 07, IPC 2.4.24.2, JIS K7095 and more integrated into the software.

Specifications

| DMA200 | |||

|---|---|---|---|

| Deformation mode options | Tension, single/dual cantilever, 3-point bending, shear, film-shear, compression | ||

| Maximum Force | 20N | ||

| Modulus Range | 103 to 1013.5 Pa | ||

| Measurement mode | Dynamic measurements: sinusoidal wave / synthesis wave oscillation modules Static measurements: program stress control / program strain control | ||

| Frequency | Sinusoidal wave oscillation: 0.01 to 200Hz, max 20 frequencies Synthesis wave oscillation mode: 5 frequencies | ||

| Temperature range | Liquid nitrogen cooling -150 to 600C | Electrical gas cooling -100 to 600C | Air cooling RT to 600C |

| Sample observation | Real View® ready | ||

| Driving shaft | Spring mounted (no compressed air required) | ||

| Sensor | LVDT | ||

| Dimensions | 420(W), x 630(D) x 725(H) mm | ||

For more information, contact us.