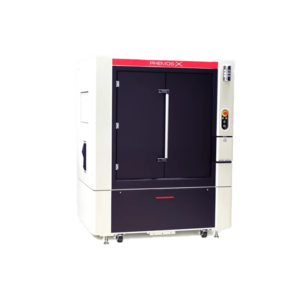

ULTRA TEC ASAP-1 Selected Area Sample Preparation System

In recent years, driven by exponential growth of newer packaging types; CSP, MCM, BGA, flip chip to name a few; in addition to ever more demanding analytical methods, the ASAP® application array has expanded to encompass mechanical decapsulation and topside de-processing.

The 2nd Generation ASAP-1® models provide the same elegant engineering approach and intuitive user interface, whilst incorporating advanced optical sample alignment and high torque motor options to handle the most ‘difficult’ sample preparations. Aesthetics and system access have also bee in proved to enhance the ease of use.

OPTICAL ALIGNMENT

Our patented ULTRACOLLIMATOR technology allows for fast, accurate and repeatable parallel alignment of the sample surfaces to the preparation system. Since the ULTRACOLLIMATOR beam aligns directly to the die, there is no guesswork or the need to use mechanical indicators. Transfer to and from the microscope is made fast and accurate. Small realignments can be made quickly and accurately.

ACCURATE, INTUITIVE SAMPLE POSITIONING

ASAP-1® incorporates controls to achieve the alignment and processing of all sizes packages and samples – from sub-mm die / FIB trenches, right up to large flip-chip CPU modules. The system provides X-Y amplitude control — providing up to 1 inch (25.4mm) maximum cavity size, or an optional 2 inch (50mm) amplitude upgrade, for large large dice and cavities.

The X-Y Independent table movement is now fitted as standard, allowing for single axis trenching and improved angular alignment. ASAP-1®‘s tilt table is maintained, allowing for ‘in package’ tilt to be accommodated, along with the ability to translate the ULTRACOLLIMATOR signal into fast accurate sample alignment.

Upgrades to the tool drive include the option for a 3X torque motor, providing the power required to optimize heavy milling and material removal.

ADVANCED, IMPROVED SYSTEM CONTROLS

The new ASAP-1® models incorporate upgraded controls – including process timer and improved traveling table and motor control. Independent Table Drive Switching, the optional LCD monitor and ULTRACOLLIMATOR are all controlled from the front panel of the unit. The LCD monitor is switchable between ULTRACOLLIMATOR and MACRO-VISION modes.

The MACRO-VISION camera provides important realtime feedback to the operator, with a magnified view of the sample surface being de-processed, polished or decapsulated.

- Suits most sizes of die

- Low damage patented floating-head polishing method allows for extremely thin samples

- Mechanical Decapsulation

- Intuitive and easy to use

- Enables layer by layer topside removal for de-processing

- Short set-up and process times

- Easy ‘on the fly’ tilt adjustment.